Insulation Systems That Ensure Uptime

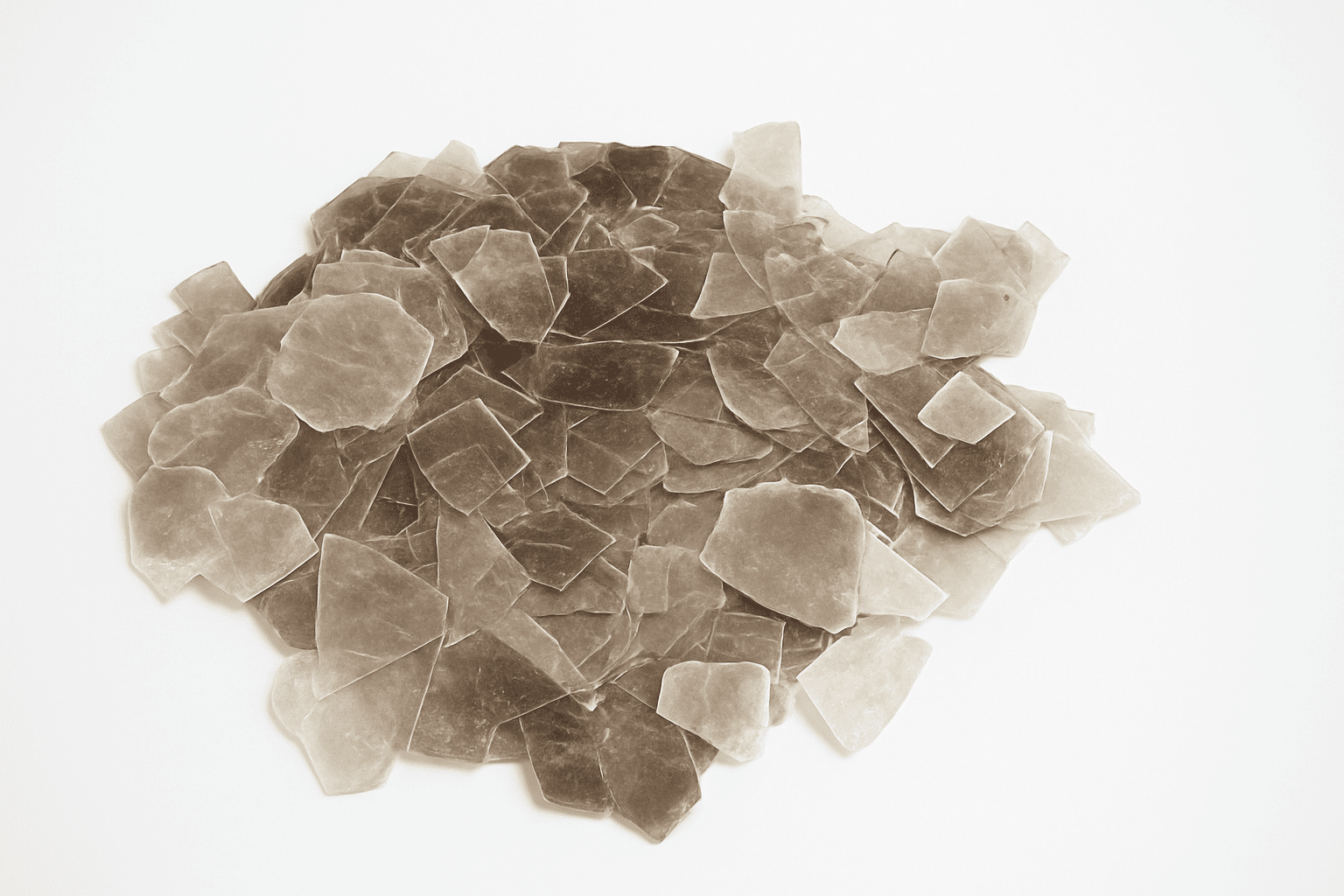

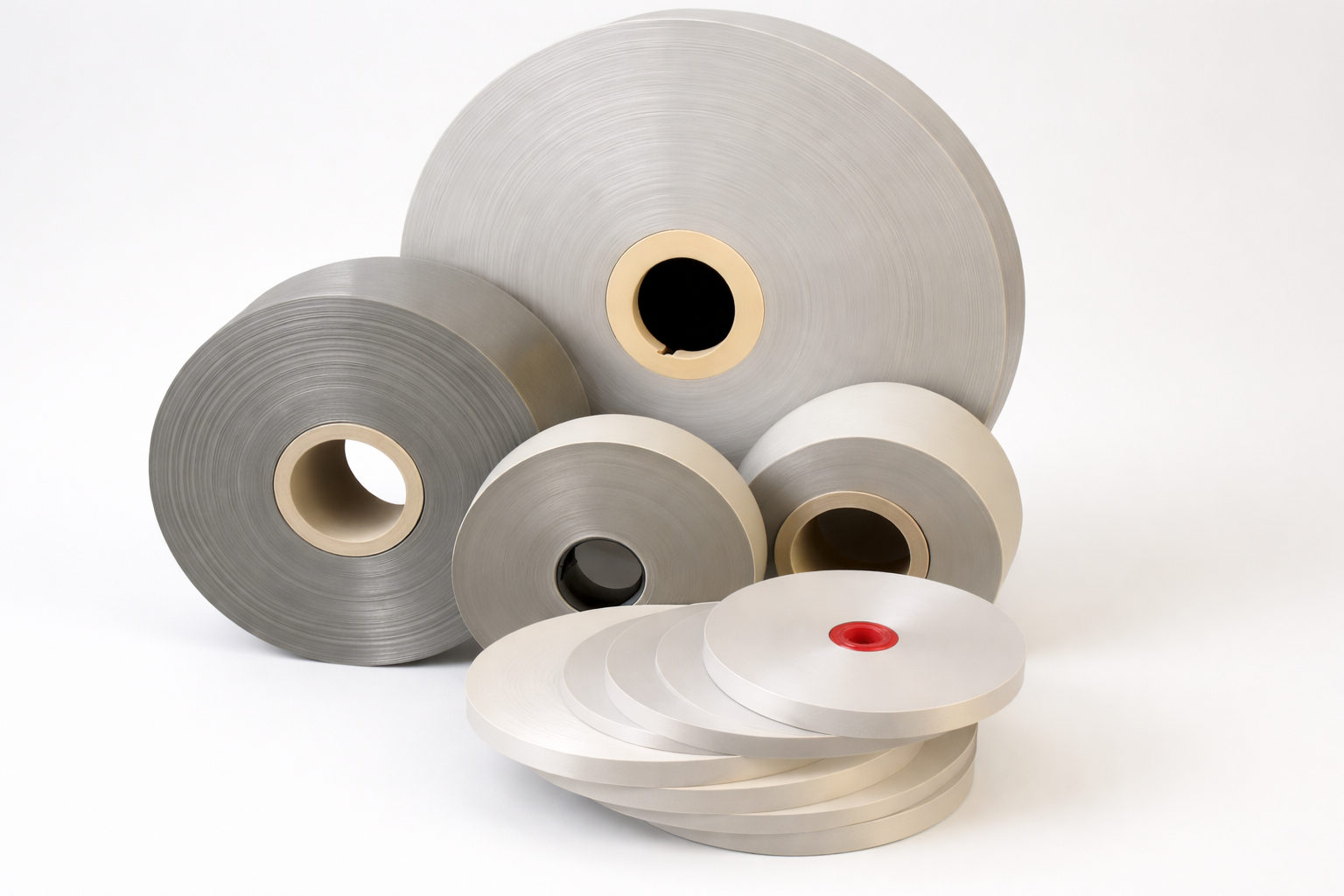

Advanced mica-based insulation technologies for high -performance rotating electrical machines.

Nippon Rika Inc. provides a comprehensive portfolio of mica-based insulation materials used in high-voltage motors and generators.

Our technologies support both Resin Rich (RR) and VPI insulation systems and are designed to deliver long service life, thermal stability, and reliable electrical performance in demanding applications.

-

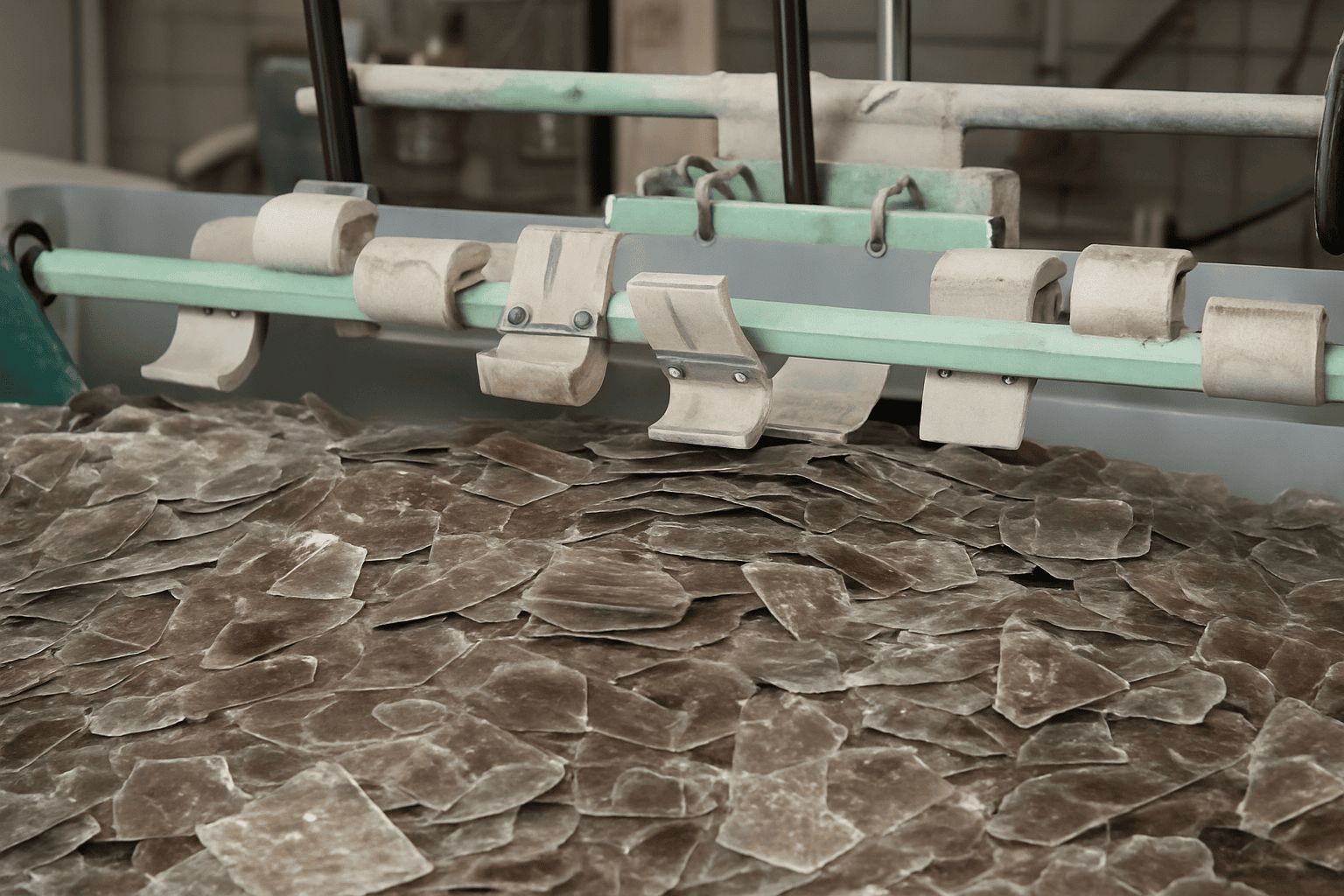

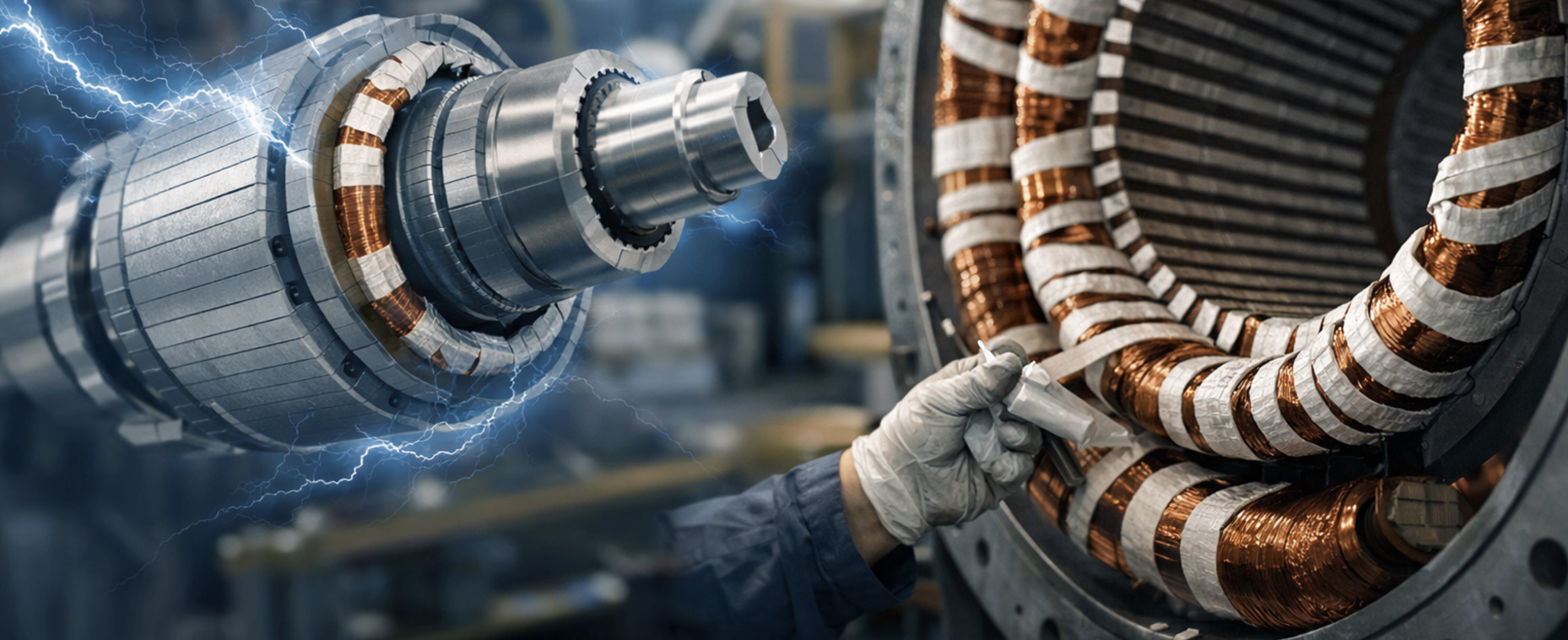

Resin Rich insulation tapes combine mica, reinforcement layers, and b-stage epoxy resin in a single material. During hot pressing, the resin flows, degasses, and cures to form a dense, void-free main wall insulation. These systems are widely used in large generators and other high voltage electrical equipment where dimensional stability, low partial discharge, and long thermal endurance are required.

Typical benefits include:

Excellent electrical performance with low PD and dissipation factor

High mechanical strength and thermal class capability

Controlled insulation thickness and reproducibility

This technology is commonly applied to stator bars, coils, and Roebel bars.

-

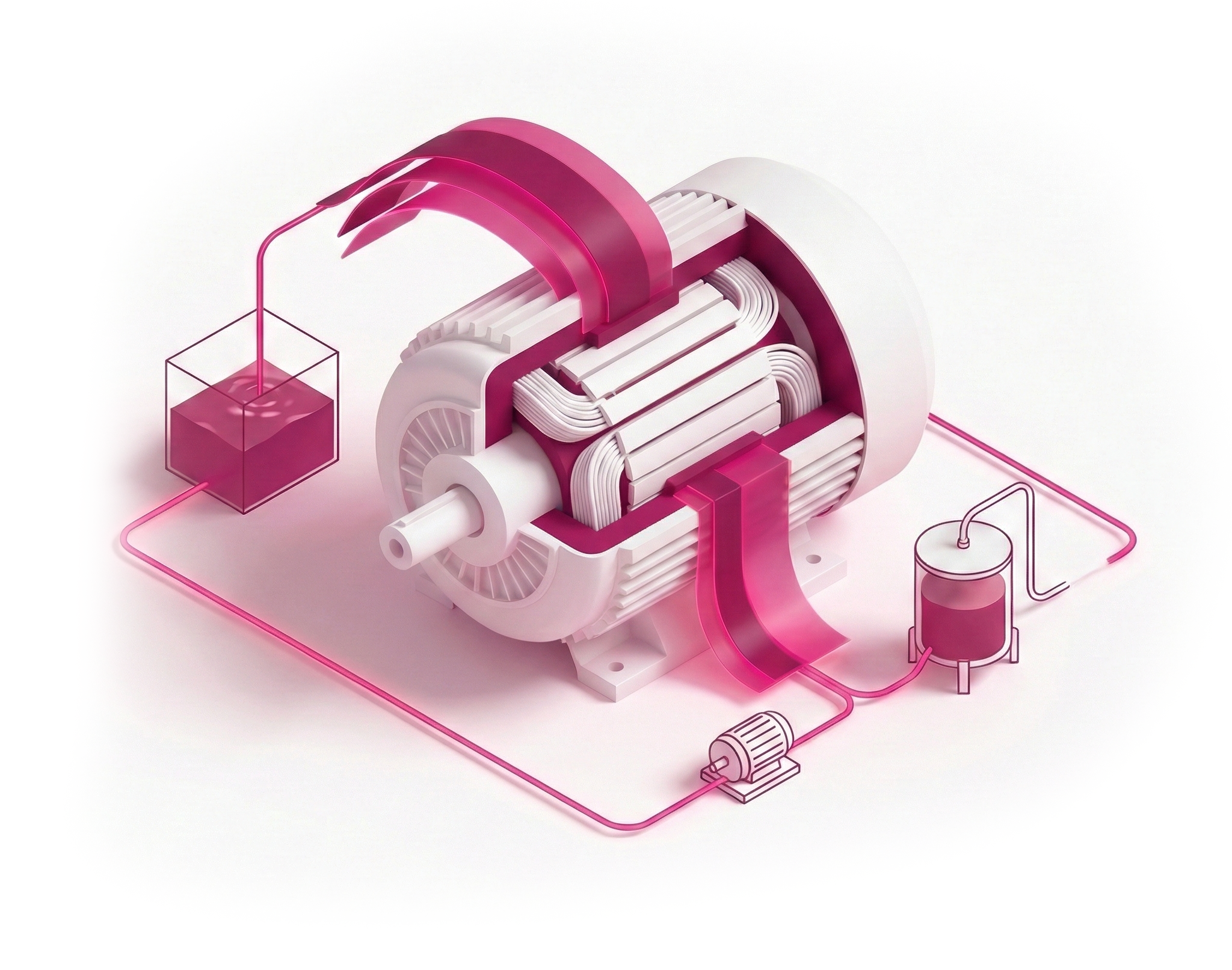

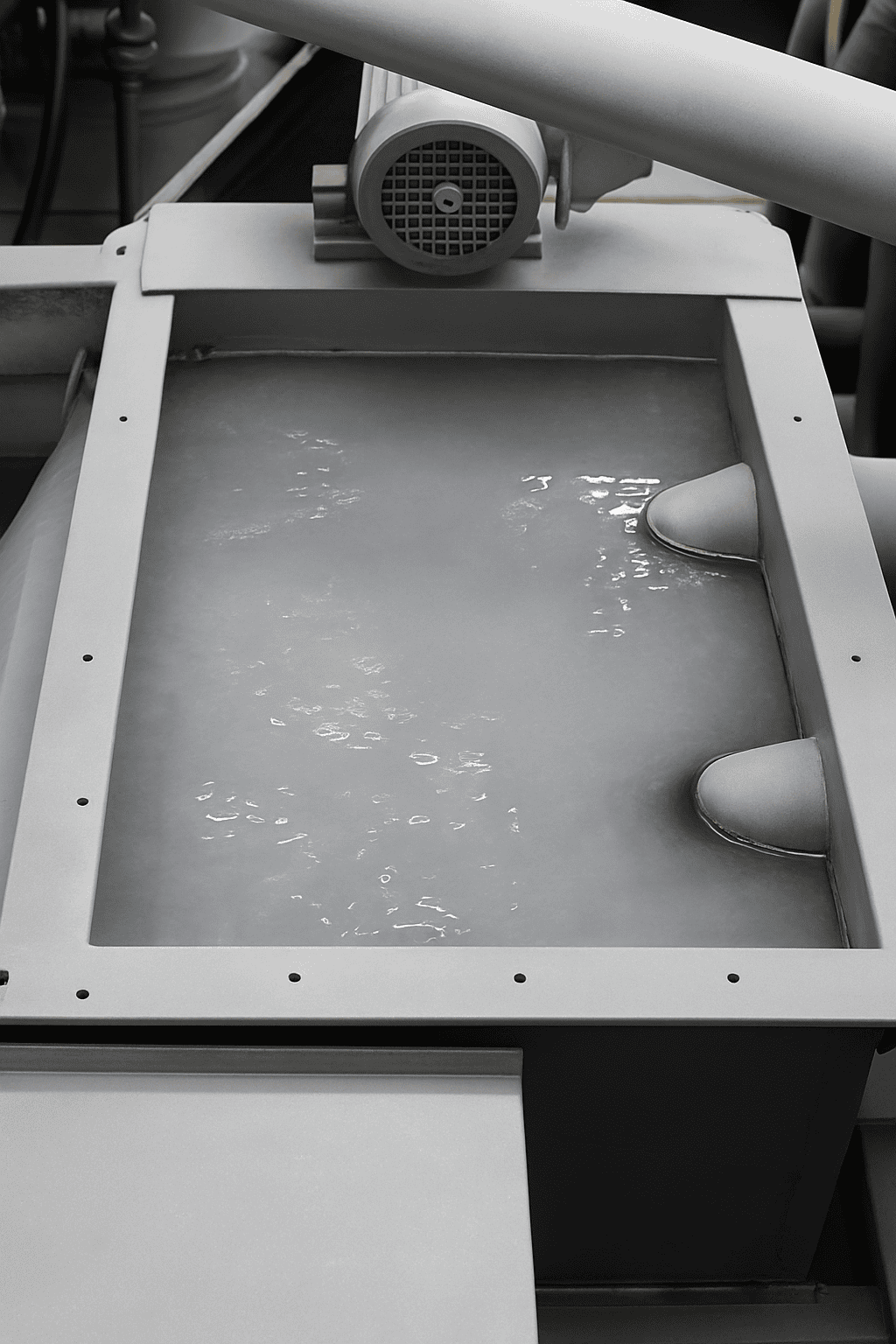

VPI systems utilize dry or resin-poor mica tapes applied to coils or bars, which are subsequently impregnated with liquid resin under vacuum and pressure. This process ensures deep resin penetration, effective air removal, and thorough wet-out of the insulation system. After impregnation and curing, a consolidated and electrically robust main wall insulation is formed.

VPI technology is widely used in medium- and high-voltage motors and generators where excellent impregnation quality, high dielectric strength, and long service life under thermal and mechanical stress are required.

Typical benefits include:

Excellent electrical performance with low partial discharge and high dielectric strength

Superior resin penetration and bonding across complex geometries

High thermal endurance and resistance to vibration and thermal cycling

Proven reliability for long-term operation in demanding environments

-

Nippon Rika’s mica tapes and system products for traction motors are trusted by leading global OEMs and widely approved for use in demanding rail and mobility applications. As a recognized market leader, we offer high-performance insulation solutions based on aramid fiber–reinforced mica paper, engineered for long-term reliability. Depending on the required temperature class, silicone binder systems are used to ensure thermal stability, mechanical integrity, and consistent processing.

-

We provide a broad range of supporting components and advanced insulation parts used in motors and generators. This includes manufactured items such as FRP air guides, wedges, insulation caps, and other critical insulation-related components, as well as selected supporting and traded materials required around the insulation system.

Our North American customers benefit from close coordination with Nippon Rika’s global manufacturing footprint and deep application know-how.